The Challenge: From Blind Spots to Baseline Understanding

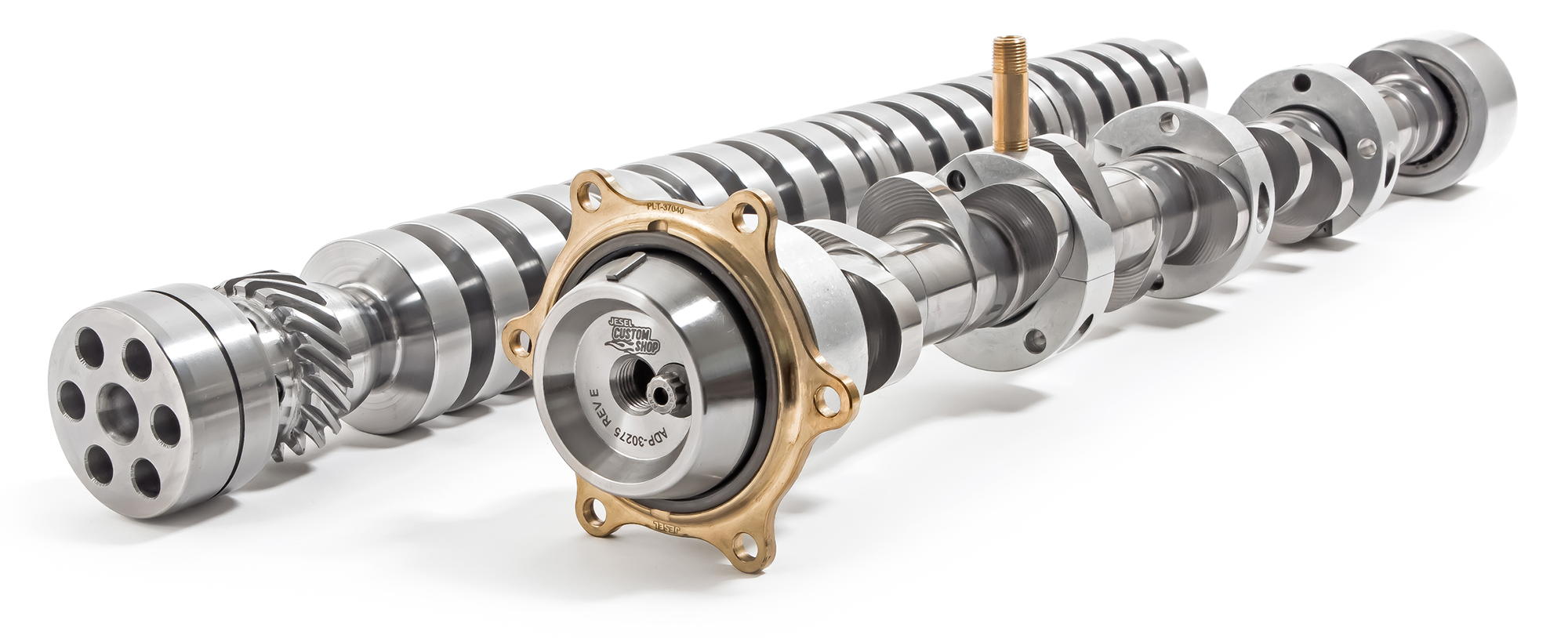

Jesel operates precision CNC machinery where every second matters and every process deviation compounds into cost and quality impacts. Yet like many manufacturers, they faced a critical gap: they lacked real-time visibility into how well each machine was actually performing.

Common manufacturing challenges plagued them:

- Unknown machine utilization - no clear picture of which machines were running at full capacity and which had hidden downtime

- OEE blindness - unable to measure overall equipment effectiveness in real-time across the shop floor

- Cycle time uncertainty - relying on theoretical times from bills of material without knowing if actual production matched planned times

- Late problem detection - deviations in setup, tooling, or processes discovered too late to prevent scrap or rework

- Reactive troubleshooting - addressing issues after they impacted production rather than catching them early

- Decision-making based on assumptions - operations managed by intuition rather than data

The result: a manufacturing operation running blind, making decisions based on estimates rather than evidence, and unable to systematically improve what they couldn't see.

The Transformation: Real-Time Visibility Becomes Operational Reality

Jesel deployed IoTFlows machine sensors and dashboards to capture real-time performance data across their CNC equipment. The impact was immediate and profound, suddenly they could see what had been invisible.

Discovering OEE: The Master Metric

Overall Equipment Effectiveness (OEE) is the gold standard metric for manufacturing performance, combining availability, performance, and quality into a single number. But you can't manage what you can't measure.

With IoTFlows, Jesel now tracks OEE continuously and displays it on accessible dashboards. Every operator, supervisor, and manager can see:

- Availability - how much of the scheduled time the machine is actually running

- Performance - how fast the machine is running compared to its theoretical maximum

- Quality - what percentage of parts produced meet specifications

This transparency transformed how the shop floor operated. Suddenly, improving OEE wasn't a vague goal, it was a visible, measurable, achievable target that everyone could see improving in real-time.

Cycle Time Validation: Theory Meets Reality

Jesel's bills of material contained cycle time estimates, the theoretical time it should take to complete each operation. But theory doesn't account for real-world variations in operator skill, tool wear, setup differences, and machine behavior.

IoTFlows changed this equation. By comparing actual measured cycle times against the times specified in the bills of material, Jesel discovered:

- Systematic deviations - certain products consistently running faster or slower than planned

- Setup inefficiencies - tooling and fixture setup taking longer than estimated

- Operator variance - experienced operators completing cycles faster than newer staff

- Tool performance degradation - cycle times increasing as tools wear

- Process improvement opportunities - where the biggest gaps existed between theory and reality

This wasn't abstract data, it was actionable intelligence that informed every manufacturing decision.

Daily Operations Transformed

"The IoTFlows Machine Sensors continue to provide us with valuable real-time data that we rely on to measure machine utilization and overall equipment effectiveness (OEE). The dashboard has become an essential tool in our daily operations, not only for monitoring how well each machine is performing, but also for quickly identifying areas that need attention, including setups, tooling performance, and other process-related issues.

I use the dashboard every day to compare and validate actual cycle times against the times listed in our bills of material. This has helped improve accuracy, highlight deviations early, and support more informed decision-making across our manufacturing processes."

Pete Gonella, Director of Manufacturing, Jesel

This isn't theoretical improvement, this is how Jesel now operates, day in and day out. The dashboard has become indispensable.

Key Operational Impacts

From Visibility to Decision-Making

Machine Utilization Clarity

- Real-time view of which machines are fully utilized and which have capacity

- Ability to balance workload across equipment based on actual performance data

- Elimination of guesswork about where bottlenecks exist

OEE as Daily Driver

- Continuous visibility into the three components of OEE (availability, performance, quality)

- Shift-by-shift comparison revealing patterns and performance trends

- Accountability tied to visible, measurable metrics

Cycle Time Intelligence

- Actual cycle times compared directly against bills of material estimates

- Early detection of deviations before they become expensive problems

- Data-driven refinement of planned cycle times based on reality

Setup and Tooling Insights

- Clear visibility into setup time variations and optimization opportunities

- Identification of tooling performance issues before quality suffers

- Continuous feedback on process-related performance drivers

Informed Decision-Making

- Operations guided by evidence rather than intuition

- Resource allocation decisions based on real performance data

- Continuous improvement initiatives targeted at the biggest impact areas

Why This Matters

In precision manufacturing, small deviations compound. A setup that runs 5 minutes slower than expected, repeated 20 times a day, becomes an hour of lost capacity. A tool that's degrading unseen creates quality issues that appear downstream. A machine running at 85% of theoretical capacity instead of 95% drains profitability across thousands of parts.

Jesel's advantage isn't investing in new equipment, it's understanding and optimizing what they already have. By making utilization, OEE, and cycle times visible, they've unlocked performance that was always there, just hidden.

The Daily Dashboard Routine

For Jesel, the IoTFlows dashboard isn't a report you check weekly. It's a tool Pete and his team consult every day:

- Morning: Review overnight production OEE to understand machine behavior

- Throughout the day: Monitor cycle times against estimates to catch deviations early

- Setup changes: Validate that new setups match planned cycle times

- Problem-solving: When a machine underperforms, the data is immediately available to diagnose why

- Decision-making: Resource allocation and production scheduling informed by real performance metrics

This daily reliance on data-driven insights has fundamentally changed the culture of manufacturing management at Jesel.

Looking Forward: Continuous Refinement

Building on the foundation of real-time OEE and cycle time visibility, Jesel is exploring advanced analytics to predict tool wear before it impacts quality, optimize setup procedures based on performance data, and leverage historical patterns to continuously refine bills of material estimates.

The vision is clear: a precision manufacturing operation where every machine's performance is visible, every decision is data-backed, and continuous improvement is built into daily operations rather than relegated to annual reviews.