The Real-Time Manufacturing Intelligence Platform

Unify machines, data, and operations with AI-powered intelligence and secure IoT connectivity. Improve uptime, optimize performance, and enable data-driven decisions across the enterprise.

Unify machines, data, and operations with AI-powered intelligence and secure IoT connectivity. Improve uptime, optimize performance, and enable data-driven decisions across the enterprise.

Trusted by Industry Leaders

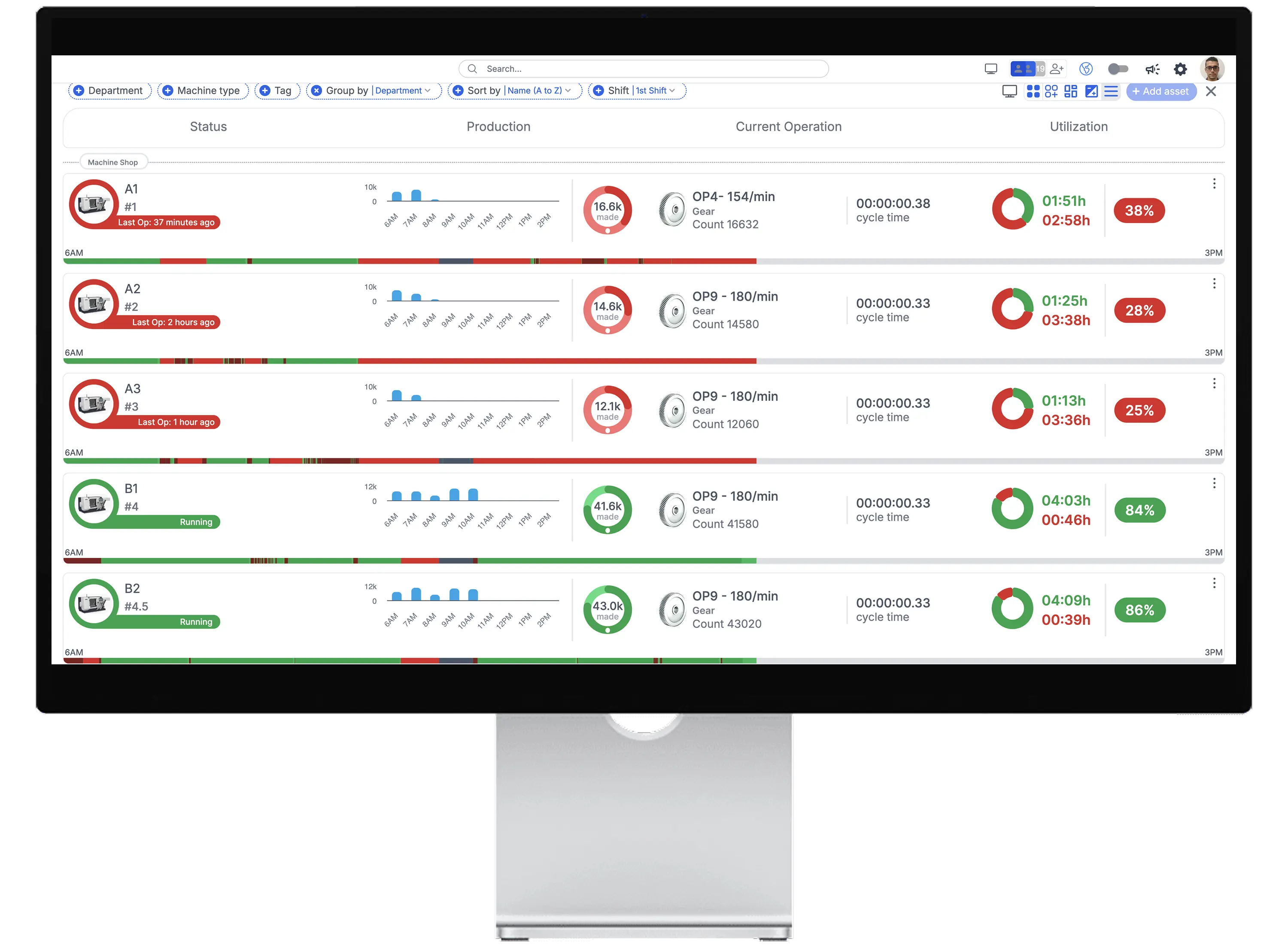

REAL-TIME PERFORMANCE & PRODUCTION TRACKING

See Every Second of Production. Hit Every Target.

Monitor OEE in real-time, spot bottlenecks the moment they occur, and track performance from individual machines to plant-wide operations.

- Live OEE monitoring and performance benchmarking across shifts

- Real-time production tracking

- Bottleneck identification and cycle time optimization

- Production variance alerts and target tracking

- Job progress visibility across all teams and production lines

DATA-DRIVEN DECISIONS

Reports That Actually Answer Your Questions

Stop digging through spreadsheets. Get reports customized to your shift schedules, operators, and departments. Track utilization, downtime patterns, and OEE metrics across across all machines.

- Daily, weekly, monthly, quarterly, and yearly reporting

- Custom shift-based performance analysis

- Operator and machine benchmarking

- Exportable data for stakeholder presentations

- Historical trend analysis

DOWNTIME INTELLIGENCE

Turn Downtime Into Insights

Unplanned stops don't have to stay a mystery. Automatically record every downtime event, identify root-causes, and spot trends over time. Know exactly when, where, and why issues occur.

- Automated downtime event recording

- Detailed root-cause analysis and categorization

- Trend identification for recurring problems

- Customizable alerts based on your specific time thresholds

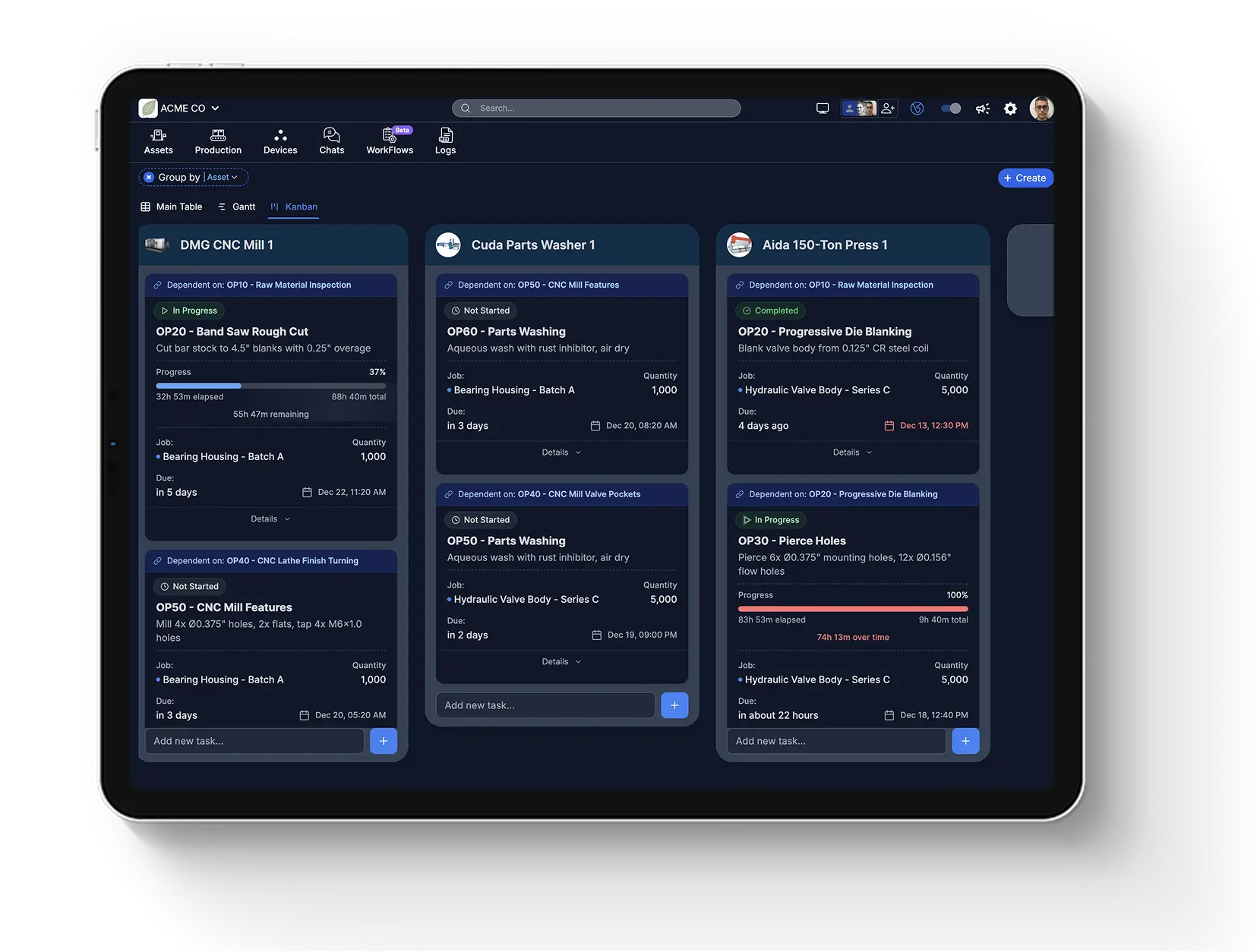

INTELLIGENT PRODUCTION PLANNING

Schedule Smarter. Execute Faster.

AI-powered scheduling that adapts to real-world conditions. Automatically prioritize jobs based on demand, monitor progress across all operations, and dynamically adjust when priorities shift.

- AI-driven job scheduling and auto-prioritization

- Demand-based production forecasting

- Live job status monitoring across all machines

- Dynamic schedule adaptation to changing priorities

- Drag-and-drop kanban interface for easy adjustments

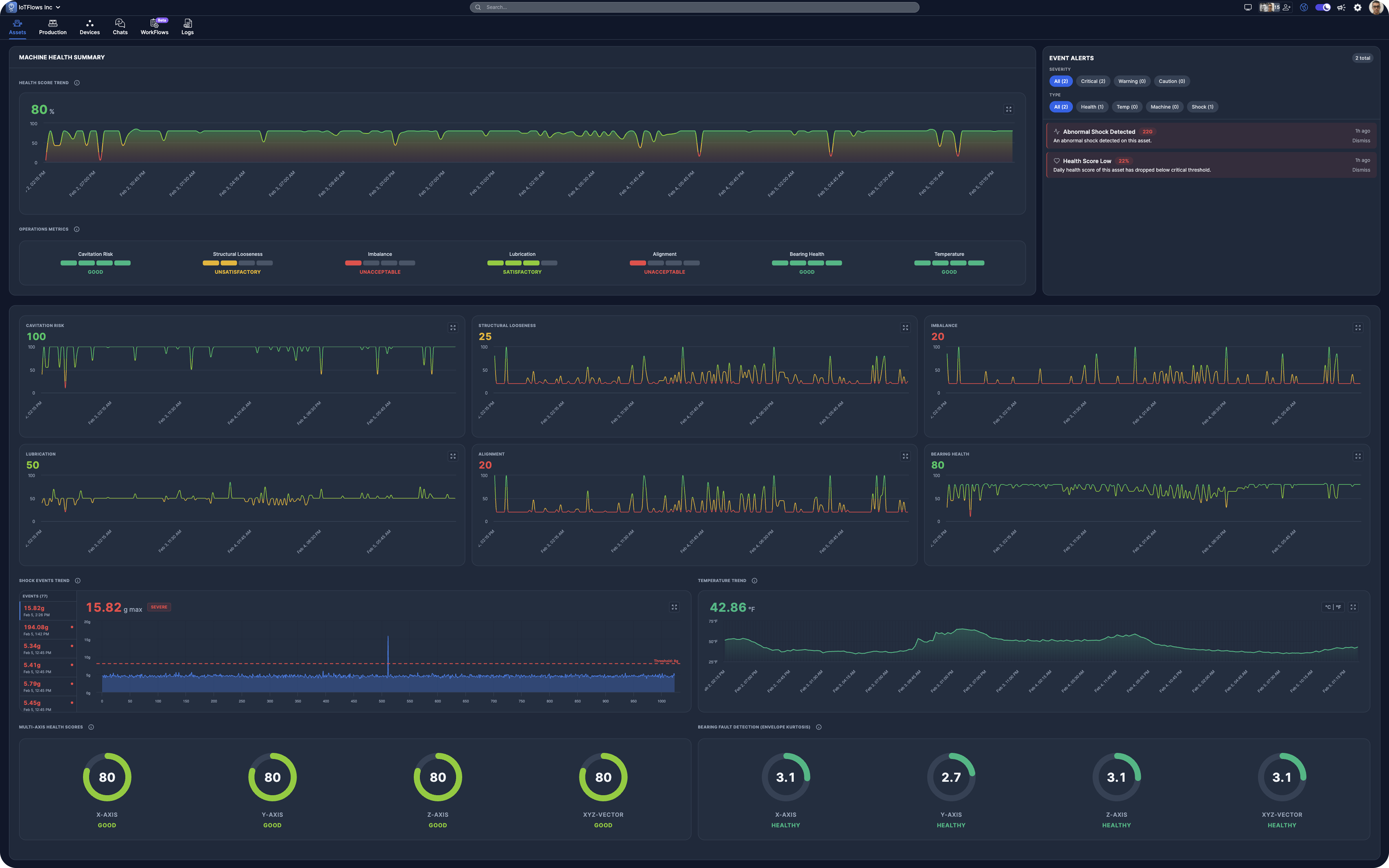

MACHINE HEALTH ANALYTICS

7 Real-Time Health Scores

Monitor every aspect of machine health with AI-powered analytics that detect issues before they become failures

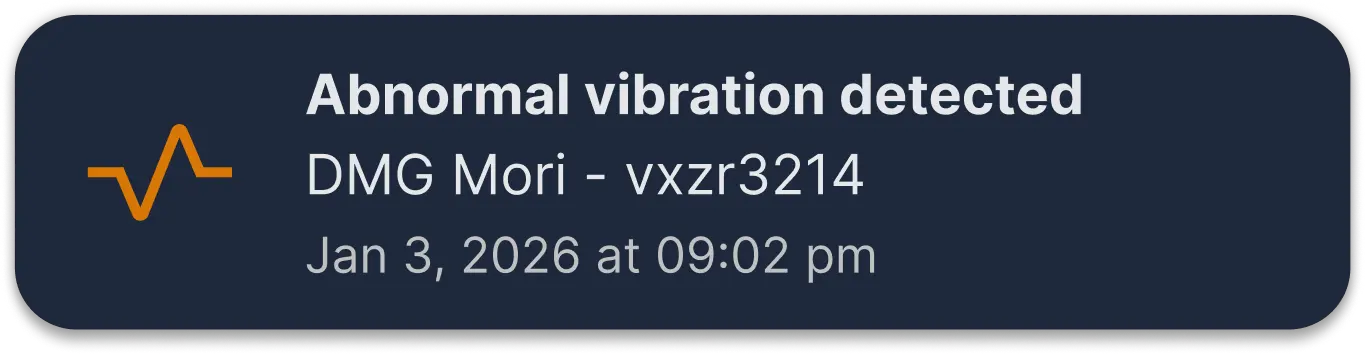

Stay Informed on Every Operation

Receive instant notifications for critical events, machine health changes, temperature anomalies, and vibration alerts. Your entire operation, monitored 24/7.

Health Monitoring

Track machine health scores and get alerted before failures occur

Temperature Alerts

Detect overheating and thermal anomalies in real-time

Vibration Detection

Monitor shock and vibration levels to prevent equipment damage

Downtime and Uptime Tracking

Get notified immediately when machines go offline or idle

Production Rate Monitoring

Get alerted when production throughput drops below targets

Part Inspection Alerts

Automatic reminders for quality checks based on parts count

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

Operator Break

15minMachine idle during scheduled operator break

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Material Shortage

18minProduction paused due to raw material depletion

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Scheduled Downtime

45minPlanned maintenance window in progress

System Recovery

Equipment successfully recovered from fault condition

Maintenance Complete

Scheduled maintenance completed, equipment operational

Line Startup Complete

Production line successfully started and running

Calibration Check Needed

950 partsSensor calibration verification due after production run

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Efficiency Declining

76%Overall equipment effectiveness trending downward

Shift Target Behind

340 unitsProduction 15% below target for current shift

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Hydraulic Overheat

92°CHydraulic system temperature critically high

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Lubrication Level Low

48%Automatic lubrication system level below threshold

Belt Tension Low

72%Drive belt tension below optimal operating range

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Machine Running

Machine is up and running

Health Score Declining

38%Gradual decrease in overall machine health detected

Unplanned Downtime

120minMachine stopped unexpectedly during production

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Temperature Rising

65°CBearing temperature trending upward

Health Score Declining

68%Gradual decrease in overall machine health detected

Extended Downtime

45minMachine has been idle for longer than scheduled

Machine Running

Machine is up and running

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Machine Health Critical

19%Overall health score has dropped below 45%

Operator Break

15minMachine idle during scheduled operator break

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Material Shortage

18minProduction paused due to raw material depletion

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Scheduled Downtime

45minPlanned maintenance window in progress

System Recovery

Equipment successfully recovered from fault condition

Maintenance Complete

Scheduled maintenance completed, equipment operational

Line Startup Complete

Production line successfully started and running

Calibration Check Needed

950 partsSensor calibration verification due after production run

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Efficiency Declining

76%Overall equipment effectiveness trending downward

Shift Target Behind

340 unitsProduction 15% below target for current shift

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Hydraulic Overheat

92°CHydraulic system temperature critically high

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Lubrication Level Low

48%Automatic lubrication system level below threshold

Belt Tension Low

72%Drive belt tension below optimal operating range

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Machine Running

Machine is up and running

Health Score Declining

38%Gradual decrease in overall machine health detected

Unplanned Downtime

120minMachine stopped unexpectedly during production

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Temperature Rising

65°CBearing temperature trending upward

Health Score Declining

68%Gradual decrease in overall machine health detected

Extended Downtime

45minMachine has been idle for longer than scheduled

Machine Running

Machine is up and running

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Machine Health Critical

19%Overall health score has dropped below 45%

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

Machine Health Critical

19%Overall health score has dropped below 45%

High Temperature Detected

78°CMotor temperature exceeding normal operating range

Production Rate Declining

68 parts/hrGradual decrease in production throughput detected

Excessive Vibration

8.2GShock levels indicate potential bearing failure

Machine Running

Machine is up and running

Extended Downtime

45minMachine has been idle for longer than scheduled

Health Score Declining

68%Gradual decrease in overall machine health detected

Temperature Rising

65°CBearing temperature trending upward

Vibration Spike

5.8GUnusual vibration pattern detected on X-axis

Inspection Overdue

1500 partsPart inspection threshold exceeded - immediate check required

Unplanned Downtime

120minMachine stopped unexpectedly during production

Health Score Declining

38%Gradual decrease in overall machine health detected

Machine Running

Machine is up and running

Quality Check Required

500 partsQuality check needed after 1000 parts processed

Slow Production Detected

45 parts/hrProduction rate has dropped below expected threshold

Bearing Wear Detected

52%Bearing signature indicates accelerated wear patterns

Motor Health Critical

28%Multiple motor parameters outside acceptable range

Belt Tension Low

72%Drive belt tension below optimal operating range

Lubrication Level Low

48%Automatic lubrication system level below threshold

Air Pressure Fluctuating

65%Pneumatic system pressure showing instability

Seal Failure Imminent

22%Seal integrity degraded - replacement urgently needed

Hydraulic Overheat

92°CHydraulic system temperature critically high

Gearbox Temperature Rising

82°CGearbox operating above normal temperature range

Cooling System Inefficient

68°CCooling system not maintaining target temperature

Thermal Runaway Detected

95°CRapid temperature increase detected in control cabinet

Cold Chain Break

12°CRefrigeration unit temperature exceeded safe range

Pasteurization Temperature

68°CProcess temperature below pasteurization minimum

Fermentation Temp Drift

23°CFermentation tank temperature drifting from setpoint

Pump Cavitation Detected

6.4GUnusual vibration signature indicates pump cavitation

Shaft Misalignment

9.1GSevere vibration indicates potential shaft misalignment

Belt Slippage Detected

4.2GIntermittent vibration patterns suggest belt slippage

Rotor Imbalance

7.3GVibration analysis indicates rotor imbalance condition

Production Line Stalled

12 parts/hrProduction rate dropped to near zero - line may be stalled

Bottleneck Detected

58 parts/hrStation 3 causing downstream flow reduction

Cycle Time Increasing

73 parts/hrAverage cycle time trending upward over past hour

Shift Target Behind

340 unitsProduction 15% below target for current shift

Efficiency Declining

76%Overall equipment effectiveness trending downward

Reject Rate Increasing

18 defects/hrQuality rejects up 12% from previous hour

Critical Inspection Required

2500 partsImmediate quality inspection needed - defect rate increasing

Scheduled Inspection Due

1200 partsRegular maintenance inspection window approaching

Tool Wear Check

850 partsCutting tool inspection recommended based on part count

Calibration Check Needed

950 partsSensor calibration verification due after production run

Line Startup Complete

Production line successfully started and running

Maintenance Complete

Scheduled maintenance completed, equipment operational

System Recovery

Equipment successfully recovered from fault condition

Scheduled Downtime

45minPlanned maintenance window in progress

Emergency Stop Triggered

0Safety system activated - machine stopped immediately

Material Shortage

18minProduction paused due to raw material depletion

Power Loss Event

32minUnexpected power interruption caused machine shutdown

Operator Break

15minMachine idle during scheduled operator break

PREDICTIVE MAINTENANCE & MACHINE HEALTH

Prevent Equipment Failures Before They Cost You

Eliminate reactive maintenance. IoTFlows uses continuous vibration monitoring and AI-driven insights to predict equipment failures days or weeks in advance. Our analytics suite detects faults early and auto-generates work orders, enabling planned maintenance instead of emergency shutdowns - while optimizing machine performance to extend equipment life and maintain peak operating efficiency.

- Continuous vibration, acoustic, and temperature monitoring with wireless sensors

- Advanced health metrics: RMS, crest factor, kurtosis, peak velocity, FFT and spectral analysis

- AI-triggered maintenance tasks based on real-world machine conditions

- Bearing failure detection, misalignment alerts, and anomaly detection

- Reduce unplanned downtime by 30% or more

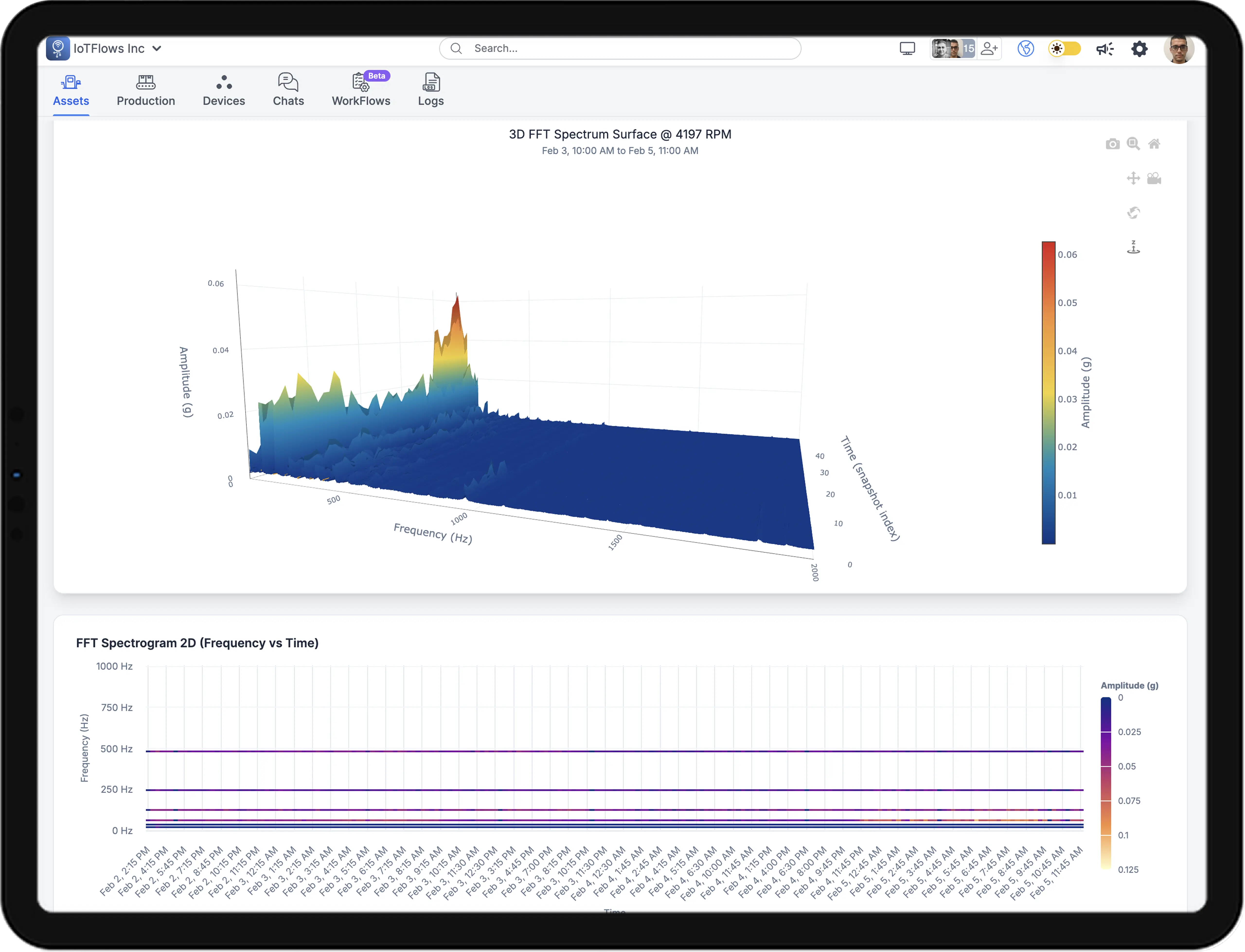

For Engineers

See the Data Behind the Insights

Unlike black-box solutions, SenseAi gives you full access to the raw data and advanced visualizations that power our AI diagnostics.

- 2D frequency spectrum with 3D waterfall visualization

- Automatic harmonic markers

- RMS Velocity (ISO 10816), peak acceleration, and crest factor trends

- Kurtosis and envelope kurtosis analysis

- Independent X, Y, Z analysis with combined XYZ vector magnitude

- Per-axis health scores and directional fault identification

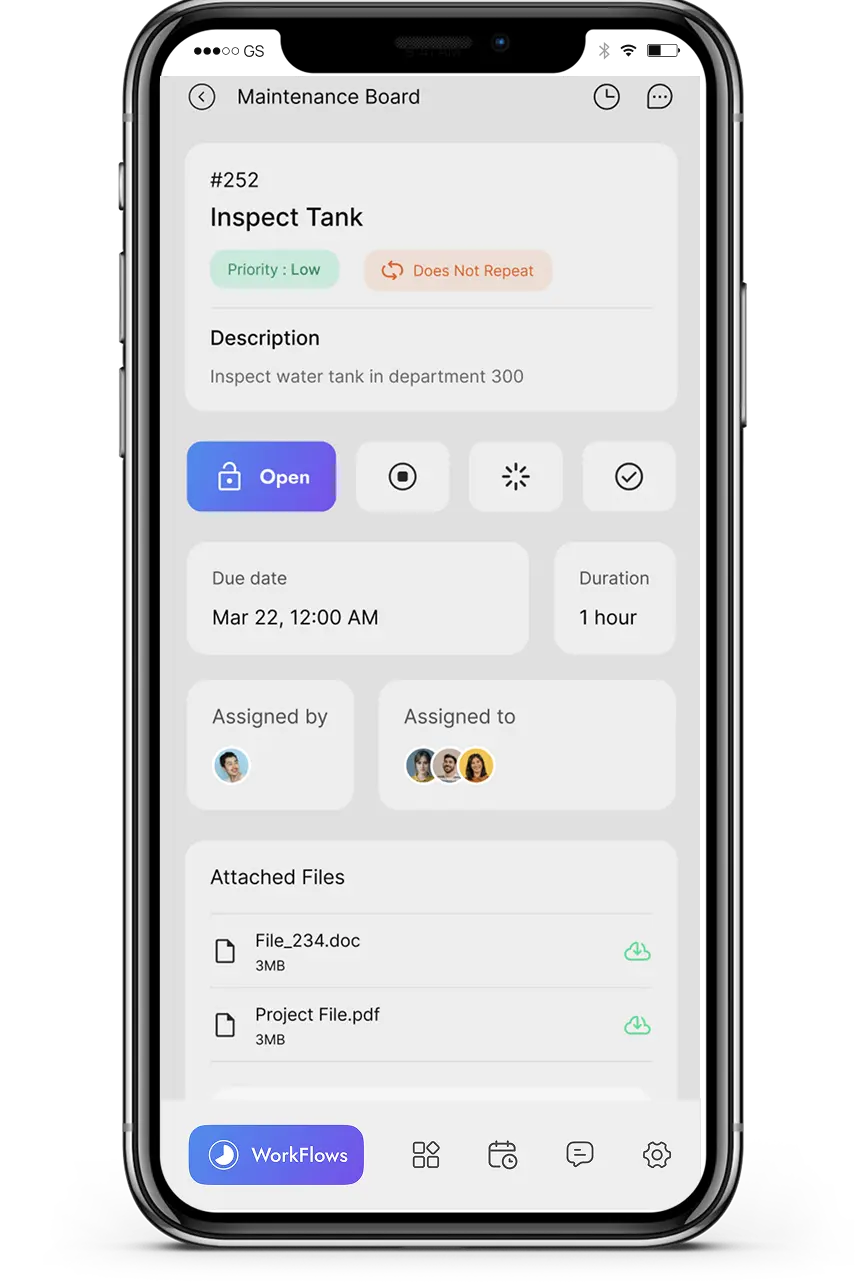

SHOP FLOOR EMPOWERMENT

Tools Built For The People Who Build Your Products

Equip your operators with intuitive tools that make hitting production goals effortless. Real-time machine status, simplified downtime tracking, and instant collaboration and file sharing - all accessible from tablets, phones, or shop floor displays.

- Intuitive iPad and mobile interface for shop floor

- One-tap downtime classification and work order creation

- Real-time machine status visibility

- Instant alerts and notifications

- Seamless collaboration between operators and management

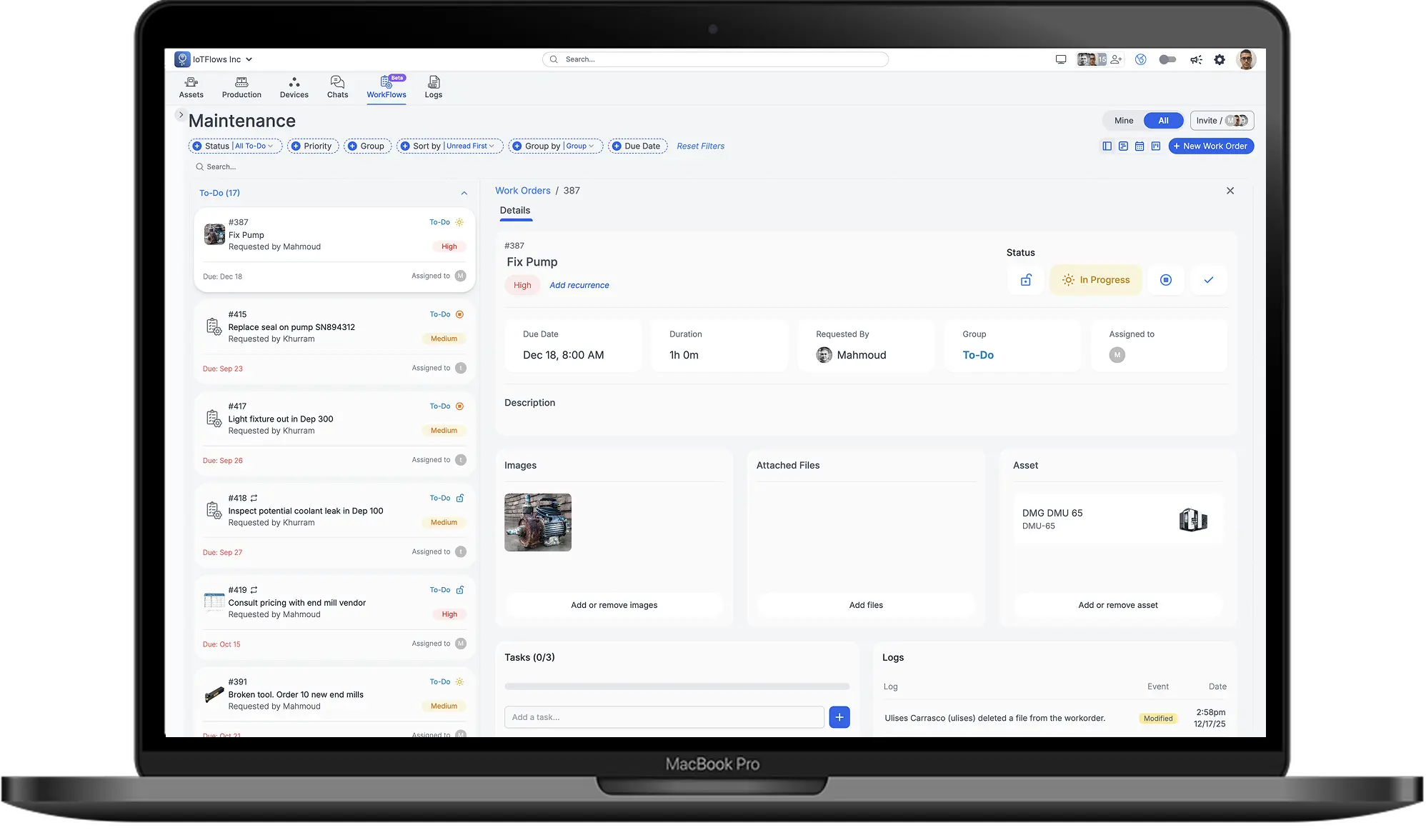

TEAM COLLABORATION & CONNECTED OPERATIONS

Align Teams. Respond Faster. Run Smarter.

Streamline communication and collaboration across your entire operation. IoTFlows empowers teams to submit maintenance requests, file issues, manage work orders, and share critical files - all from one unified platform. Track jobs in real-time, coordinate team assignments, and ensure everyone from operators to managers stays informed and aligned.

- Real-time mobile alerts and instant notifications

- Collaborative downtime classification and root-cause tracking

- Unified job progress visibility across all teams and shifts

- Work order integration and maintenance workflow automation

- Cross-functional communication from floor to executive level

ENTERPRISE INTEGRATION & DATA UNIFICATION

Break Down Data Silos. Automate Across Systems.

Stop manually bridging the gap between shop floor and top floor. IoTFlows unifies production data from across your facility—then seamlessly integrates with your ERP, and other business systems. Enable real-time visibility across departments, trigger automated workflows based on production events, and eliminate manual data entry. Your operations data becomes the single source of truth that drives smarter decisions and faster response times.

- Bi-directional ERP integration: SAP, Oracle, Epicor, and many more

- Seamless data sync capabilities eliminate manual entry and reduce errors

- Real-time production visibility for finance, operations, and management

- Event-driven automation: trigger workflows, notifications, and actions

- API-first architecture for custom integrations and advanced automation

Start Monitoring Your Machines Today

Join 100+ industrial customers who trust IoTFlows to optimize their operations.