SenseAi

SenseAi is a plug-and-play AI-powered vibration monitoring system that delivers real-time visibility into machine performance. Track utilization and OEE, detect downtime instantly, and improve uptime by 30% with root-cause analysis. Perfect for CNC machines, injection molding, presses, robot arms, and production lines.

Trusted by Industry Leaders

Transform the way you work

Complete Production Visibility

Gain real-time insights across your entire operation—machines, teams, and jobs. Our AI sensors capture every detail, from OEE and downtime patterns to job progress and root causes, helping you identify top performers and uncover training opportunities instantly.

- Live machine utilization monitoring

- OEE & downtime root cause analysis

- Job progress tracking across all operations

- Performance benchmarking & insights

Intelligent Production Scheduling

Transform how you schedule and forecast production with AI-powered planning tools. Automatically prioritize jobs based on demand, monitor ongoing work, and dynamically adjust schedules to hit your targets—even when priorities shift.

- AI-driven job scheduling & auto-prioritization

- Demand-based production forecasting

- Live job status monitoring

- Dynamic schedule adaptation

Seamless Team Collaboration

Equip your workforce with intuitive tools that make hitting daily production goals effortless. Enable real-time collaboration between machines and people, streamline downtime tracking, and keep everyone aligned on job changes—so operators can focus on value-added work.

- Simplified downtime classification

- Real-time machine-human collaboration

- Unified job progress visibility

- Built-in operator support tools

Drive Capacity & Margin Growth

Discover exactly what production bottlenecks are costing you and prioritize improvements that deliver real impact. Pinpoint downtime drivers, quantify the financial impact of issues, and unlock hidden capacity to boost both throughput and profitability.

- Downtime cost calculation & analysis

- Root cause identification for bottlenecks

- Capacity expansion opportunities

- ROI tracking for improvements

IoTFlows SenseAi Platform Features Overview

Complete Production Visibility

Gain real-time insights across your entire operation—machines, teams, and jobs. Our AI sensors capture every detail, from OEE and downtime patterns to job progress and root causes, helping you identify top performers and uncover training opportunities instantly.

- Live machine utilization monitoring

- OEE & downtime root cause analysis

- Job progress tracking across all operations

- Performance benchmarking & insights

Intelligent Production Scheduling

Transform how you schedule and forecast production with AI-powered planning tools. Automatically prioritize jobs based on demand, monitor ongoing work, and dynamically adjust schedules to hit your targets—even when priorities shift.

- AI-driven job scheduling & auto-prioritization

- Demand-based production forecasting

- Live job status monitoring

- Dynamic schedule adaptation

Seamless Team Collaboration

Equip your workforce with intuitive tools that make hitting daily production goals effortless. Enable real-time collaboration between machines and people, streamline downtime tracking, and keep everyone aligned on job changes—so operators can focus on value-added work.

- Simplified downtime classification

- Real-time machine-human collaboration

- Unified job progress visibility

- Built-in operator support tools

Drive Capacity & Margin Growth

Discover exactly what production bottlenecks are costing you and prioritize improvements that deliver real impact. Pinpoint downtime drivers, quantify the financial impact of issues, and unlock hidden capacity to boost both throughput and profitability.

- Downtime cost calculation & analysis

- Root cause identification for bottlenecks

- Capacity expansion opportunities

- ROI tracking for improvements

Simplicity

Effortlessly Monitor Your Machines with SenseAi

Unlock the full potential of your manufacturing operations with SenseAi's plug-and-play, AI-powered monitoring solution. SenseAi magnetically attaches to your machines in seconds, instantly tracking efficiency metrics, downtime patterns, and root causes—giving you complete visibility without disrupting production.

Key Features:

- Plug-and-play installation with 2-minute setup

- Real-time efficiency tracking and OEE monitoring with 4G cellular connectivity

- Automatic downtime detection, classification, and alerting

- AI-powered root cause analysis to identify recurring issues

- Monitor multiple facilities or production lines with unified dashboards

Visibility

Gain visibility into your manufacturing processes like never before

Transform your operations with complete visibility into efficiency, downtime, and production performance across all machines, shifts, and departments.

- Track real-time OEE, utilization rates, and efficiency metrics with instant alerts on performance drops

- Automatic downtime classification and root cause tracking to identify recurring bottlenecks

- Compare machine and operator performance across shifts, departments, and time periods

Optimize

Track part production, operations, and cycle times in one simple view

Maximize efficiency with real-time cycle time analysis, automated downtime tracking, and actionable insights that pinpoint exactly where production is being lost. Whether managing a single line or multiple facilities, SenseAi helps you identify bottlenecks, eliminate waste, and make data-driven decisions that directly improve throughput and profitability.

2-Minute Setup

Step 1

Connect Power Supply

Step 2

Attach to Machine

Step 3

Get Insights

Operator View

Empower Your Shop-floor with Real-Time Production Visibility

Empower your operators with real-time machine status, instant downtime alerts, and simple tools to classify issues and create work orders on the spot. With automated notifications for unclassified downtimes and performance drops, your team can respond immediately—reducing mean time to resolution and keeping production flowing smoothly.

Downtime and Root Cause Analysis

Turn Downtime Into Insights

Unplanned stops don't have to stay a mystery. SenseAi automatically detects, classifies, and tracks every downtime event across all your machines—capturing when, where, why, and how often issues occur. With powerful root cause analysis and downtime trending, you can identify recurring patterns, quantify their impact on efficiency, and prioritize fixes that deliver the biggest gains in uptime and throughput.

Reports

Insights into Manufacturing Machine Performance

Get the full story behind your operations with comprehensive reports that track efficiency, downtime root causes, OEE trends, and shift-by-shift performance. View daily snapshots or analyze long-term patterns across weeks, months, or years. Every report includes downtime classifications, root cause breakdowns, and actionable insights—empowering your team to make data-driven decisions that boost productivity and profitability.

Notifications

AI-Powered Monitoring for Uninterrupted Production

Never miss a critical issue with intelligent, real-time alerts. SenseAi automatically notifies the right people when machines go down, when downtimes remain unclassified, or when downtime durations exceed expected thresholds. Customize alert rules to match your operation—whether it's extended idle time, efficiency drops, or abnormal vibrations—and ensure your team can respond immediately to minimize production losses and maintain peak performance.

How much are your machines worth to you?

Number of machines needed to be optimized

How much is one hour of machine time worth to you?

ROI per machine per year with SenseAi

$

How did we get this number?

Time optimized per machine per day

30 minutes

Weeks worked per year

48

Total cost of SenseAi per year

$

Total ROI per year

$

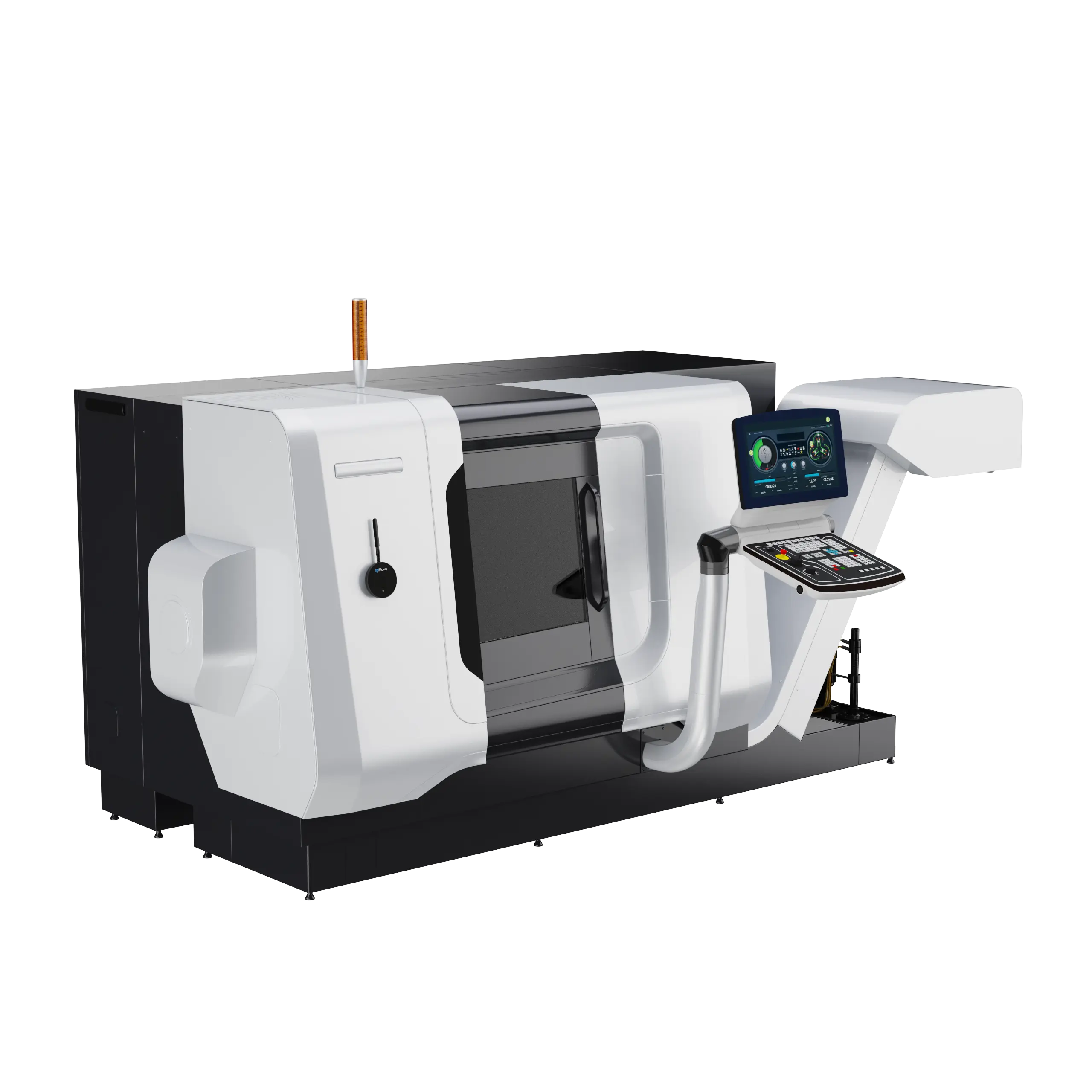

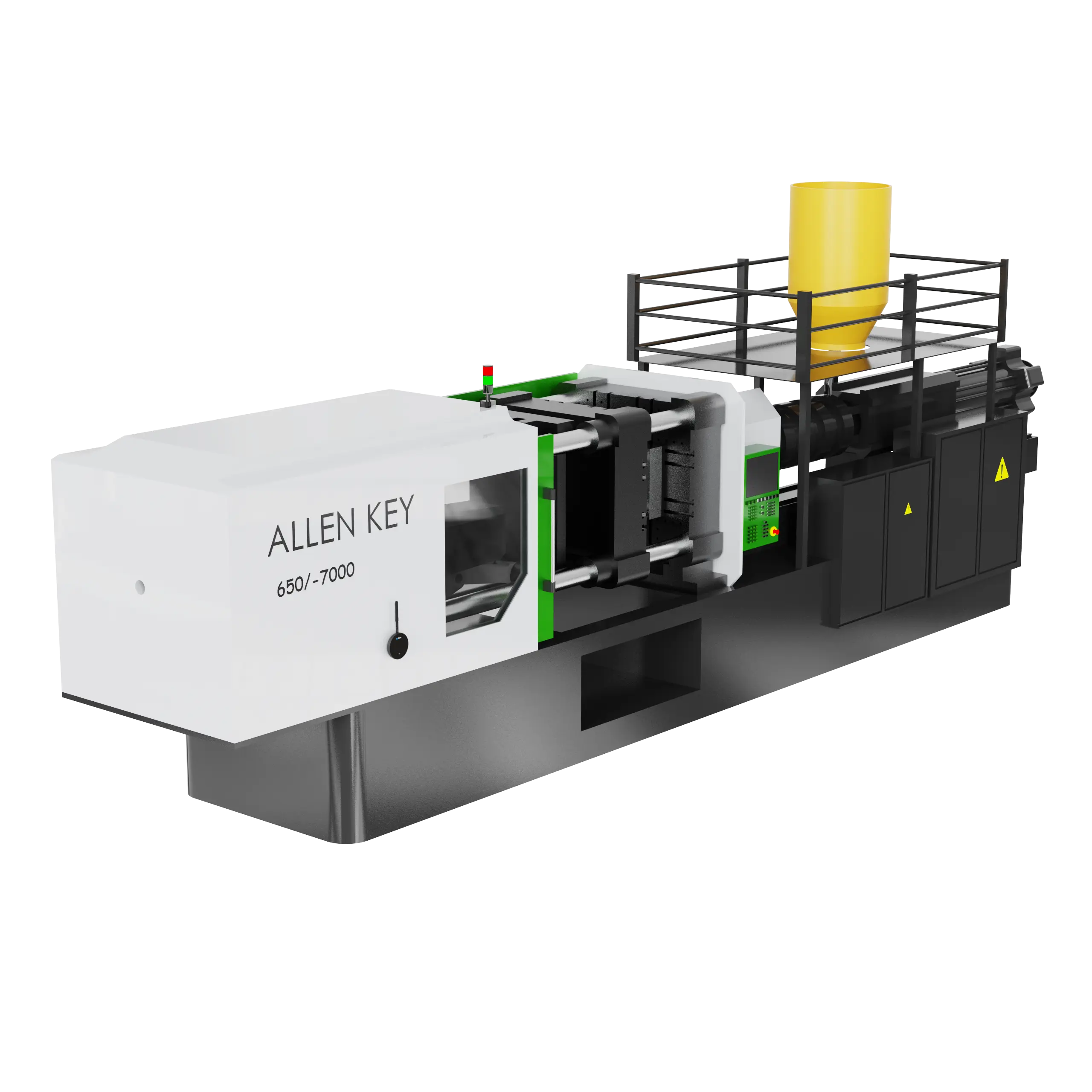

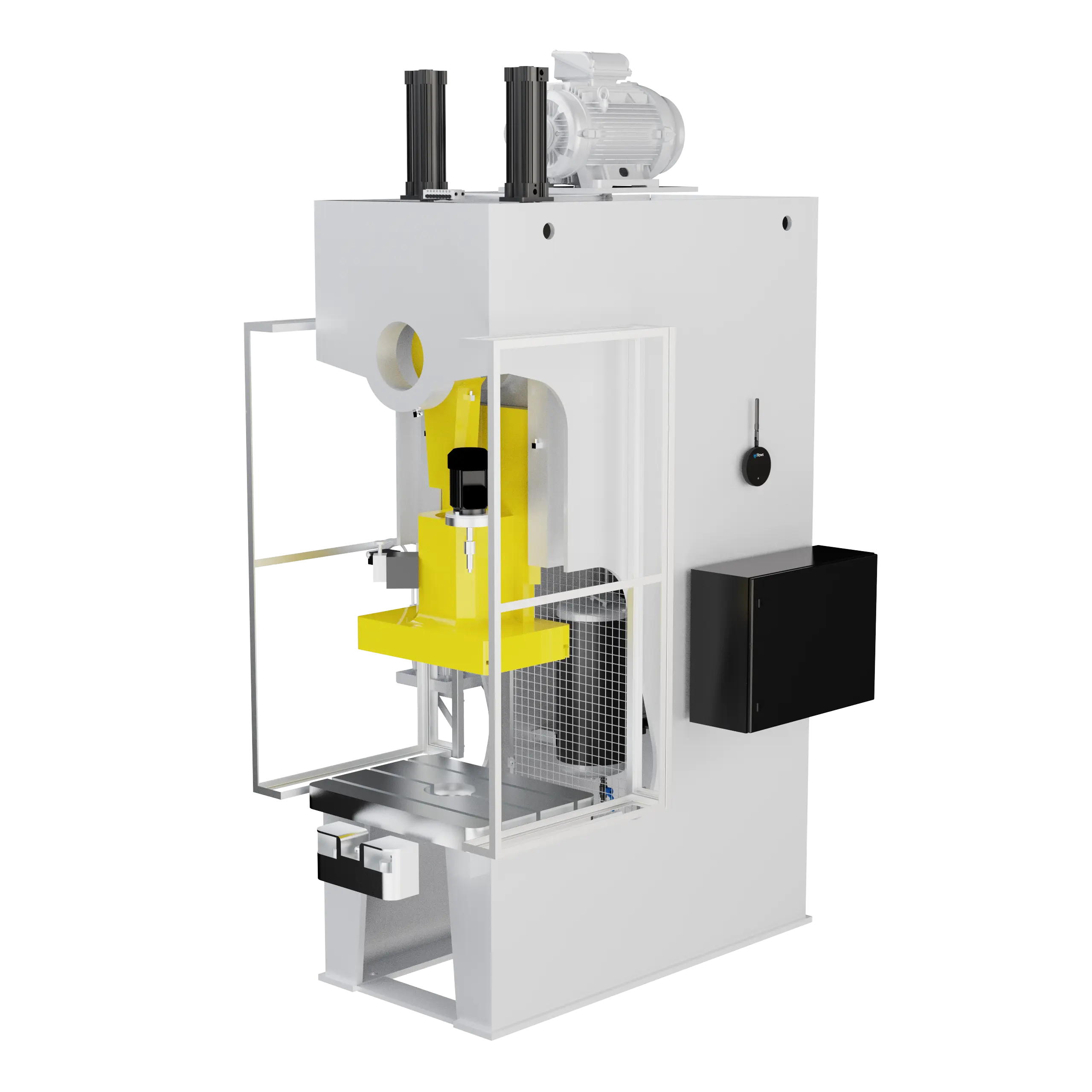

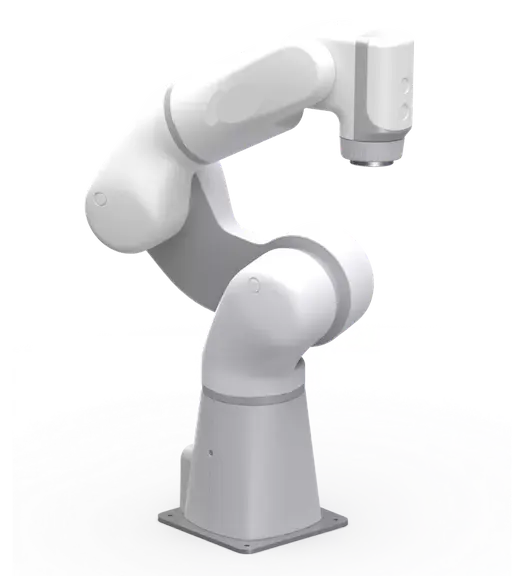

Optimized for Your Most Valued Assets

CNC Mill/Turn

Injection Molding

Press Brake

Robot Arm

FAQ

SenseAi is a smart vibration and acoustic monitoring sensor that instantly digitizes your manufacturing equipment. Simply attach it magnetically to any machine with a motor—no wiring, no machine integration, no technical expertise required. Within minutes, you'll see real-time utilization, production rates, and downtime insights on your dashboard.

SenseAi works with any industrial equipment that has vibration sources like motors: CNC machines, press brakes, injection molding machines, robot arms, waterjets, EDM machines, stamping presses, and complete production lines. If it has a motor and a metal surface, SenseAi can monitor it.

SenseAi is our magnetic plug-and-play sensor with vibration and acoustic monitoring, perfect for most manufacturing environments. SenseAi Embedded features an IP67-rated aluminum casing with M12 waterproof cable and power connection, designed for harsher environments. It provides vibration and temperature monitoring along with advanced health metrics including peak vibration, RMS, crest factor, kurtosis, FFT analysis, and velocity trends—giving you deeper insights into machine condition alongside production performance.

Installation takes less than 2 minutes per machine. Scan the QR code, attach the magnetic sensor (or mount SenseAi Embedded), connect to Wi-Fi, and you're done—no production downtime, no PLC integration, no compatibility issues. Start seeing real-time insights immediately.

SenseAi offers two simple connectivity options: connect directly to your existing Wi-Fi network, or use our secure 4G/LTE router for a completely air-gapped setup with no connection to your facility network or machines. The 4G/LTE option is perfect for isolated environments or facilities with strict network security policies.

No. SenseAi is truly plug-and-play. You don't need knowledge of MTConnect, OPC UA, Modbus, or any industrial protocols. No wiring, no machine network integration, no expensive on-site integration. IoTFlows experts will help you calibrate the sensors for your specific machines and mounting locations.

SenseAi helps you maximize machine utilization and eliminate hidden downtime. Get instant visibility into production performance, automatically track OEE, identify bottlenecks in real-time, reduce unplanned downtime with fast root cause analysis, and optimize scheduling based on actual machine and operator performance data.

SenseAi automatically detects and classifies downtimes based on rules you configure. Operators and managers receive instant notifications for unclassified or extended downtimes. Your team can quickly classify issues, create work orders, and track resolution—all from the mobile app or dashboard. Root cause analysis shows you patterns over time so you can prevent recurring issues.

Get real-time and historical reports customized to your shift schedules, operators, and departments. Track machine utilization, production counts, downtime reasons, and OEE metrics. View performance day-by-day, week-by-week, or analyze trends over months, quarters, or years. Dive deep into specific machines and time periods to understand exactly when and why issues occurred—all automated.

Yes. We provide Google TV streaming devices with the built-in IoTFlows Android app for real-time dashboard display on TV screens throughout your facility. Simply customize your dashboard with dark/light mode, view preferences, and filters, then share it to a TV device for instant visibility. Perfect for keeping your entire team informed on the shop floor.

Yes. You have full access to all configurations, calibration settings, and downtime classification rules. Set up automatic downtime categorization, configure notification triggers, define shift schedules, assign operators, organize by departments, and customize reports to match your workflows. IoTFlows experts assist with initial calibration to ensure accuracy.

View all your data through the SenseAi web dashboard, iOS app, or Android app from anywhere. Display real-time dashboards on TV screens using our Google TV devices, access insights on the shop floor, or review performance metrics remotely—your production data is always at your fingertips.

Yes. SenseAi features a modern tech stack with multiple integration options: REST API, MQTT API, webhooks, and ready-to-go integrations. Pull or push data—whether raw sensor data or processed insights, real-time or historical—to your ERP, MES, CMMS, or other systems. Check our documentation to get started, or contact support@iotflows.com for integration assistance and custom solutions.

Yes. Receive instant notifications for machine downtime, unclassified events, or downtimes exceeding expected durations. Alerts go to the right people at the right time so your team can respond immediately and minimize production losses.

Standard SenseAi includes industrial-grade vibration and acoustic sensors with magnetic mounting, a 10-foot USB-C cable, and power block. SenseAi Embedded features IP67-rated aluminum casing with M12 waterproof cable and power connection for harsh environments. Choose Wi-Fi connectivity using your existing network, or order our 4G/LTE router for an air-gapped, network-isolated setup.

Most manufacturers see measurable improvements in machine utilization and reduced downtime within the first month. By automatically tracking performance, identifying inefficiencies, and enabling data-driven decisions, SenseAi typically pays for itself quickly through increased productivity and eliminated waste.

All data is protected with SHA-256 encryption during transmission and storage. Every account includes optional two-factor authentication (2FA) for enhanced security and compliance. Plus, our 4G/LTE router option provides complete network isolation for maximum security.

SenseAi is designed for manufacturing leaders who want to maximize equipment effectiveness and eliminate production waste. Ideal users include operations managers, plant managers, production supervisors, process engineers, manufacturing engineers, and anyone responsible for improving shop floor performance.

We provide comprehensive onboarding calls, sensor calibration assistance, technical support, and ongoing guidance to ensure you get maximum value from day one. Our team helps you configure the system for your specific machines, workflows, and reporting needs. Contact support@iotflows.com anytime for help.

Yes. SenseAi provides visibility into machine efficiency and operator performance by shift, helping you identify bottlenecks, optimize scheduling, improve training, and enhance collaboration between production and maintenance teams.