SenseAi Embedded

SenseAi Embedded is an industrial-grade IP67-rated monitoring system engineered for harsh manufacturing environments. With its rugged aluminum alloy enclosure and M12 waterproof connectors, it delivers advanced machine health insights including vibration analysis, temperature monitoring, anomaly detection, health scores, FFT analysis, and predictive maintenance capabilities—alongside complete production monitoring for CNC spindles, precision equipment, and critical rotating machinery.

Trusted by Industry Leaders

Advanced Health Monitoring & Production Intelligence

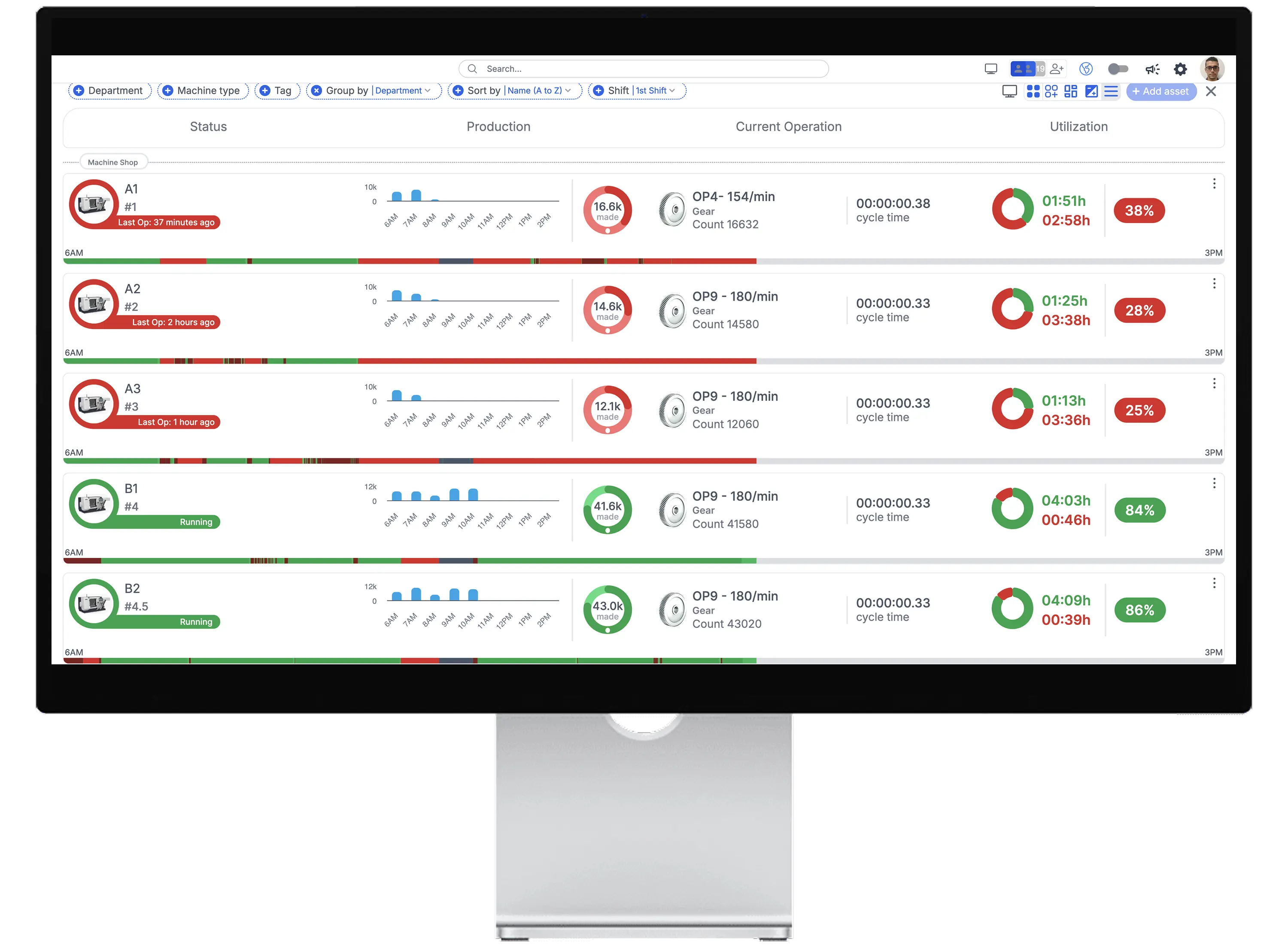

Complete Production Visibility

Gain real-time insights across your entire operation—machines, teams, and jobs. Our AI sensors capture every detail, from OEE and downtime patterns to job progress and root causes, helping you identify top performers and uncover training opportunities instantly.

- Live machine utilization monitoring

- OEE & downtime root cause analysis

- Job progress tracking across all operations

- Performance benchmarking & insights

Intelligent Production Scheduling

Transform how you schedule and forecast production with AI-powered planning tools. Automatically prioritize jobs based on demand, monitor ongoing work, and dynamically adjust schedules to hit your targets—even when priorities shift.

- AI-driven job scheduling & auto-prioritization

- Demand-based production forecasting

- Live job status monitoring

- Dynamic schedule adaptation

Seamless Team Collaboration

Equip your workforce with intuitive tools that make hitting daily production goals effortless. Enable real-time collaboration between machines and people, streamline downtime tracking, and keep everyone aligned on job changes—so operators can focus on value-added work.

- Simplified downtime classification

- Real-time machine-human collaboration

- Unified job progress visibility

- Built-in operator support tools

Drive Capacity & Margin Growth

Discover exactly what production bottlenecks are costing you and prioritize improvements that deliver real impact. Pinpoint downtime drivers, quantify the financial impact of issues, and unlock hidden capacity to boost both throughput and profitability.

- Downtime cost calculation & analysis

- Root cause identification for bottlenecks

- Capacity expansion opportunities

- ROI tracking for improvements

Industrial Durability

Built for the Harshest Manufacturing Environments

SenseAi Embedded is engineered for manufacturers who need industrial-grade monitoring in demanding conditions. With an IP67-rated aluminum alloy enclosure, M12 waterproof connectors, and industrial magnets for secure mounting, it thrives where standard sensors fail—from coolant spray and washdown areas to high-vibration and extreme temperature environments.

Industrial Features:

- IP67-rated aluminum alloy enclosure

- M12 waterproof connector with 12-24VDC power

- Industrial vibration accelerometer

- Precision temperature sensor for mounting surface

- Two strong magnets for secure installation

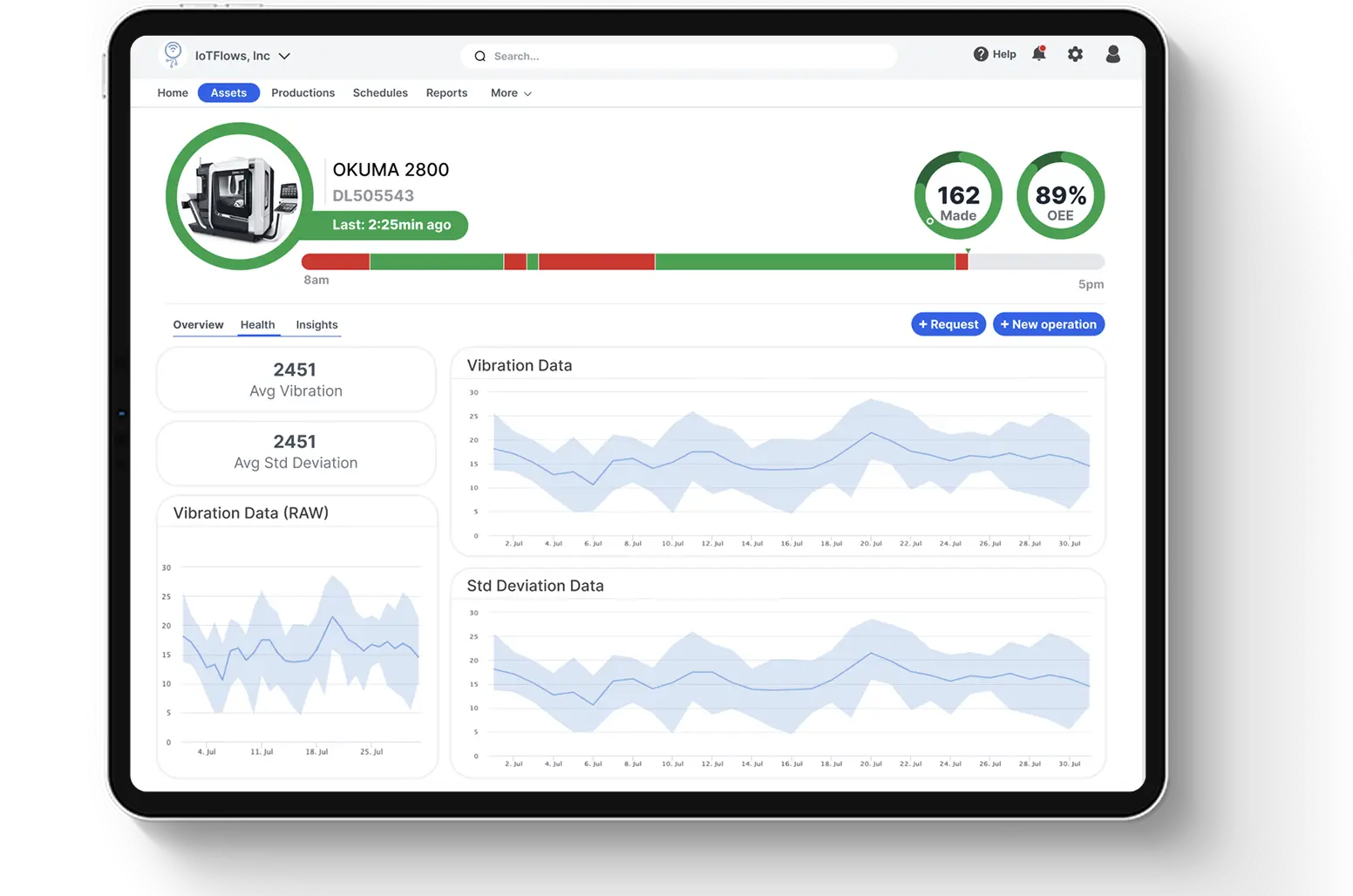

Advanced Analytics

Comprehensive Machine Health Metrics

SenseAi Embedded delivers industrial-grade health monitoring with advanced vibration analytics and temperature sensing. Get instant visibility into machine condition with comprehensive metrics designed for predictive maintenance and reliability engineering.

- Anomaly detection with AI-powered health scores

- FFT (Fast Fourier Transform) frequency analysis

- Peak vibration, RMS, crest factor, and kurtosis

- Velocity trends and acceleration patterns

- Mounting surface temperature monitoring

- Trending and historical analysis

Visibility

Gain visibility into your manufacturing processes like never before

Transform your operations with complete visibility into efficiency, downtime, and production performance across all machines, shifts, and departments.

- Track real-time OEE, utilization rates, and efficiency metrics with instant alerts on performance drops

- Automatic downtime classification and root cause tracking to identify recurring bottlenecks

- Compare machine and operator performance across shifts, departments, and time periods

5-Minute Installation

Step 1

Connect Power Supply

Step 2

Attach to Equipment

Step 3

Get Insights

Optimize

Track part production, operations, and cycle times in one simple view

Maximize efficiency with real-time cycle time analysis, automated downtime tracking, and actionable insights that pinpoint exactly where production is being lost. Whether managing a single line or multiple facilities, SenseAi helps you identify bottlenecks, eliminate waste, and make data-driven decisions that directly improve throughput and profitability.

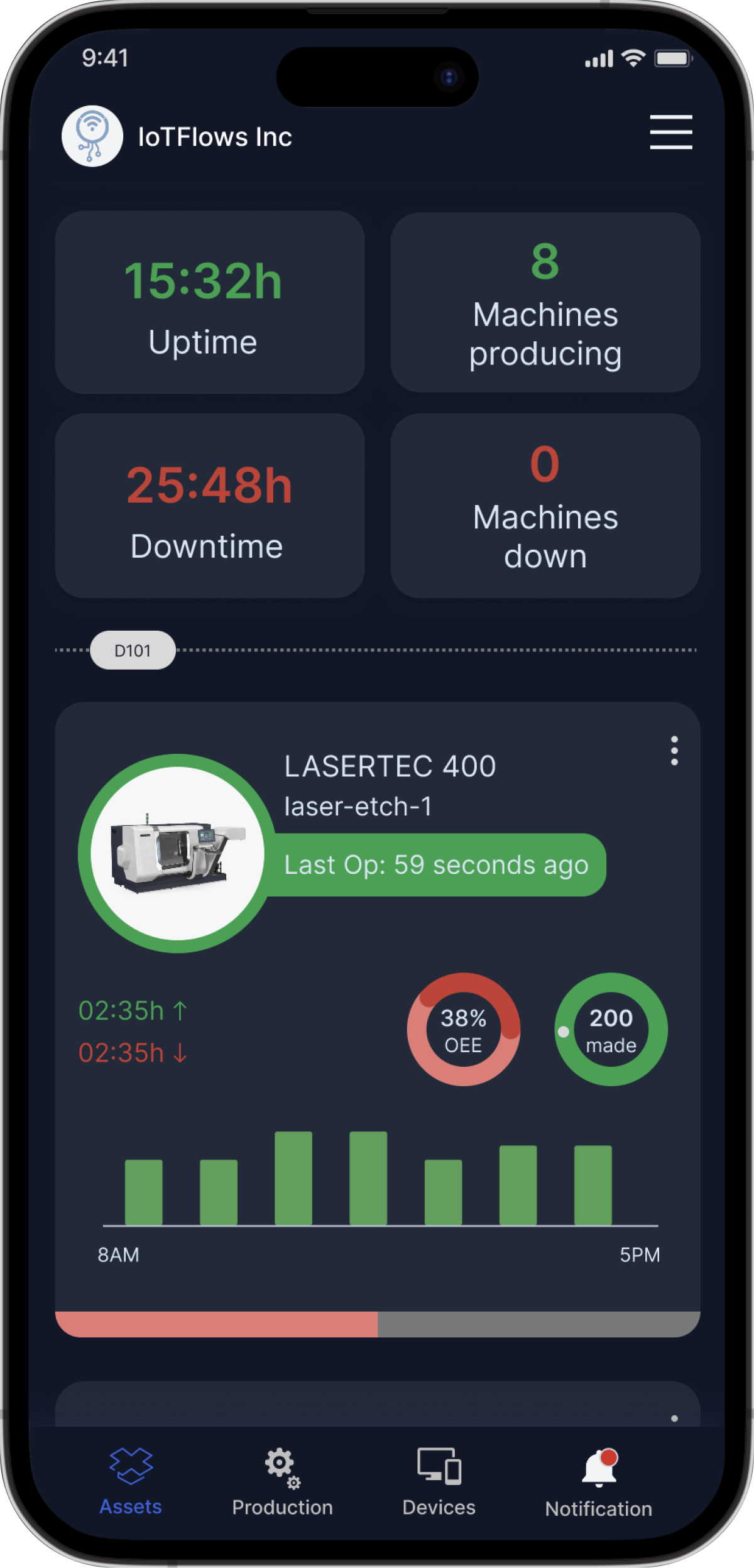

Operator View

Empower Your Shop-floor with Real-Time Production Visibility

Empower your operators with real-time machine status, instant downtime alerts, and simple tools to classify issues and create work orders on the spot. With automated notifications for unclassified downtimes and performance drops, your team can respond immediately—reducing mean time to resolution and keeping production flowing smoothly.

Downtime and Root Cause Analysis

Turn Downtime Into Insights

Unplanned stops don't have to stay a mystery. SenseAi automatically detects, classifies, and tracks every downtime event across all your machines—capturing when, where, why, and how often issues occur. With powerful root cause analysis and downtime trending, you can identify recurring patterns, quantify their impact on efficiency, and prioritize fixes that deliver the biggest gains in uptime and throughput.

Reports

Insights into Manufacturing Machine Performance

Get the full story behind your operations with comprehensive reports that track efficiency, downtime root causes, OEE trends, and shift-by-shift performance. View daily snapshots or analyze long-term patterns across weeks, months, or years. Every report includes downtime classifications, root cause breakdowns, and actionable insights—empowering your team to make data-driven decisions that boost productivity and profitability.

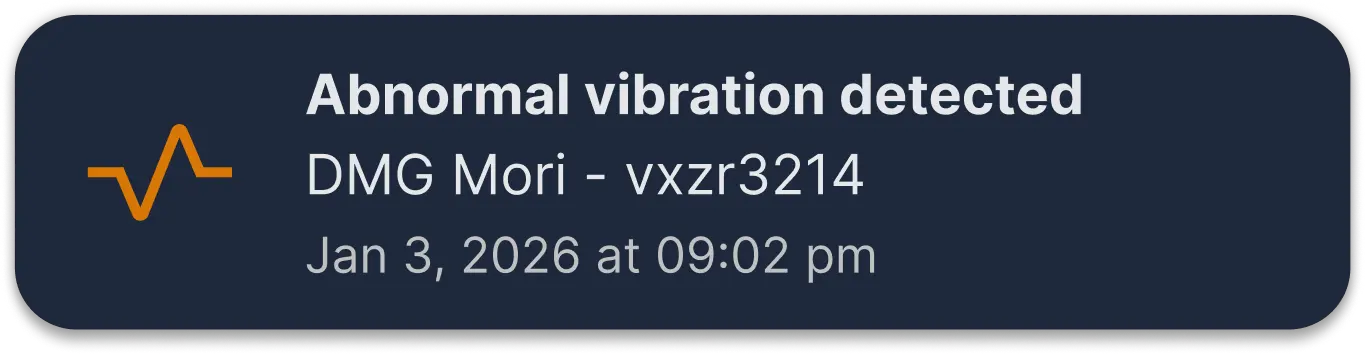

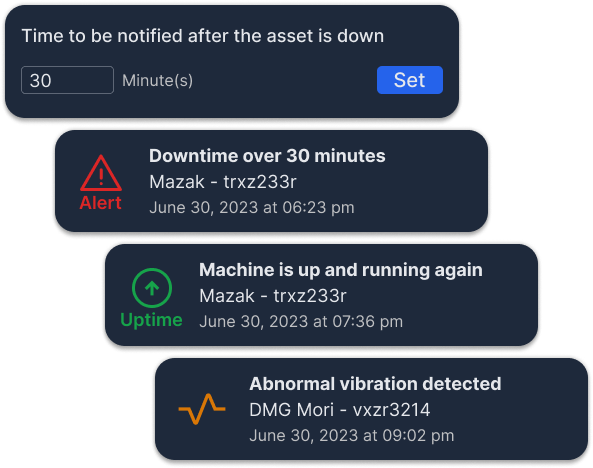

Notifications

AI-Powered Monitoring for Uninterrupted Production

Never miss a critical issue with intelligent, real-time alerts. SenseAi automatically notifies the right people when machines go down, when downtimes remain unclassified, or when downtime durations exceed expected thresholds. Customize alert rules to match your operation—whether it's extended idle time, efficiency drops, or abnormal vibrations—and ensure your team can respond immediately to minimize production losses and maintain peak performance.

Engineered for Critical Equipment

CNC Spindles

Monitor spindle vibration, temperature, and health in real-time. Detect bearing wear, imbalance, and misalignment before catastrophic failure occurs.

Precision Machining Centers

Track machine health metrics alongside production data. Optimize preventive maintenance schedules and maximize uptime on critical equipment.

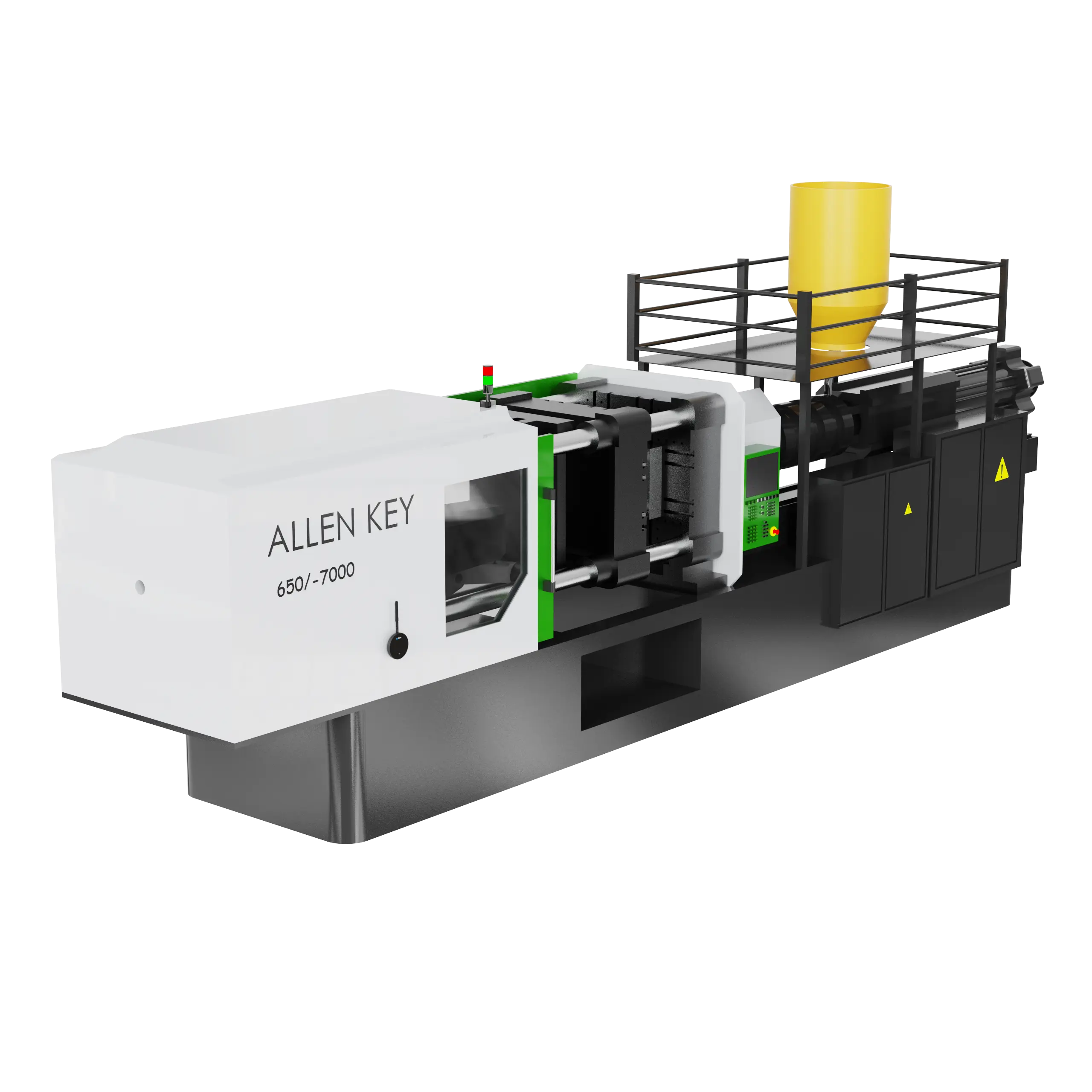

Injection Molding

Automatically capture runtime, downtimes, and root causes for every molding cycle. Receive instant alerts for extended downtimes, track efficiency trends, and optimize scheduling to maximize production runs.

Robot Arm

Track pick-and-place cycles, movement patterns, and downtime events with intelligent alerting. Identify efficiency drops, classify stoppages, and ensure your automation consistently delivers peak performance.

Press Brake

Monitor bending cycles, setup times, and operator efficiency with automated downtime tracking. Classify delays, analyze root causes, and eliminate hidden losses to boost throughput on your forming operations.

FAQ

SenseAi Embedded is an industrial-grade vibration and temperature monitoring sensor designed for harsh manufacturing environments. With its IP67-rated aluminum alloy enclosure and M12 waterproof connector, it provides advanced machine health insights including anomaly detection, health scores, vibration trends, crest factor, peak vibration, RMS, and more—alongside complete production monitoring capabilities.

SenseAi Embedded features an IP67-rated aluminum alloy enclosure for harsh industrial environments, M12 waterproof connections instead of USB-C, and includes advanced health monitoring metrics like temperature sensing, crest factor, kurtosis, FFT analysis, and velocity trends. It focuses on vibration and temperature monitoring without acoustic sensors, making it ideal for condition-based maintenance and predictive analytics in demanding applications like CNC spindles and critical rotating equipment.

SenseAi Embedded is optimized for critical rotating equipment and high-precision machines: CNC spindles, precision machining centers, industrial pumps, motors, compressors, gearboxes, bearings, and any equipment where vibration and temperature analysis are essential for preventing failures and maximizing uptime.

SenseAi Embedded requires a 12-24VDC power supply via its M12 waterproof connector. The M12 power supply can be purchased directly from our online store and ensures reliable operation in industrial environments.

SenseAi Embedded delivers comprehensive machine health metrics including: anomaly detection, health scores, trending analysis, crest factor, peak vibration, RMS (Root Mean Square), kurtosis, FFT (Fast Fourier Transform) analysis, velocity trends, and mounting surface temperature monitoring. These insights enable predictive maintenance, early fault detection, and condition-based monitoring.

SenseAi Embedded includes a precision temperature sensor that measures the temperature of the mounting surface, providing critical thermal data about your equipment. Temperature changes can indicate bearing failures, lubrication issues, misalignment, or excessive friction—giving you early warning of potential problems.

Yes. SenseAi Embedded can generate instant alerts based on vibration thresholds, temperature anomalies, health score changes, or trend deviations. These alerts can automatically trigger work orders in your CMMS or maintenance management system, ensuring rapid response to potential equipment failures.

IP67 rating means SenseAi Embedded is fully protected against dust ingress and can withstand immersion in water up to 1 meter for 30 minutes. This makes it ideal for harsh environments with coolant spray, washdown procedures, high humidity, dust, and extreme conditions where standard sensors would fail.

Installation takes less than 5 minutes. SenseAi Embedded features two strong industrial magnets for secure mounting to any metal surface. Simply attach to your equipment, connect the M12 power supply, and the sensor automatically begins collecting vibration and temperature data. IoTFlows experts will help calibrate the sensor for your specific equipment and mounting location.

Yes. SenseAi Embedded includes all the production monitoring features of standard SenseAi: utilization monitoring, production tracking, downtime root cause analysis, OEE calculation, shift reporting, and operator performance analytics. You get both machine health insights and production visibility in one industrial-grade device.

SenseAi Embedded offers the same connectivity options as standard SenseAi: connect directly to your existing Wi-Fi network, or use our secure 4G/LTE router for a completely air-gapped setup with no connection to your facility network. The 4G/LTE option is perfect for isolated environments or facilities with strict network security policies.

SenseAi Embedded is ideal for precision manufacturing, aerospace, automotive, oil & gas, pharmaceutical production, food & beverage processing, chemical processing, and any industry with critical rotating equipment where unplanned downtime is extremely costly and equipment health monitoring is essential.

Yes. SenseAi Embedded features a modern tech stack with multiple integration options: REST API, MQTT API, webhooks, and ready-to-go integrations. Pull or push data—whether raw sensor data, processed health metrics, or production insights—to your ERP, MES, CMMS, or other systems. Check our documentation or contact support@iotflows.com for integration assistance.

SenseAi Embedded includes the IP67-rated aluminum alloy sensor with industrial vibration accelerometer and temperature sensor, two strong magnets for mounting, M12 waterproof cable, and a 1-year warranty. The M12 12-24VDC power supply is available separately in our online store. Choose Wi-Fi connectivity or add our 4G/LTE router for network isolation.

By preventing even a single unplanned failure on critical equipment, SenseAi Embedded typically pays for itself immediately. Manufacturers see measurable improvements through reduced downtime, extended equipment life, optimized maintenance schedules, and the ability to plan repairs during scheduled maintenance windows rather than emergency shutdowns.

All data is protected with SHA-256 encryption during transmission and storage. Every account includes optional two-factor authentication (2FA) for enhanced security and compliance. Plus, our 4G/LTE router option provides complete network isolation for maximum security in sensitive environments.

We provide comprehensive onboarding calls, sensor calibration assistance, vibration analysis training, technical support, and ongoing guidance to ensure you get maximum value from day one. Our team helps you configure the system for your specific equipment, set appropriate thresholds, and interpret health metrics. Contact support@iotflows.com anytime for help.